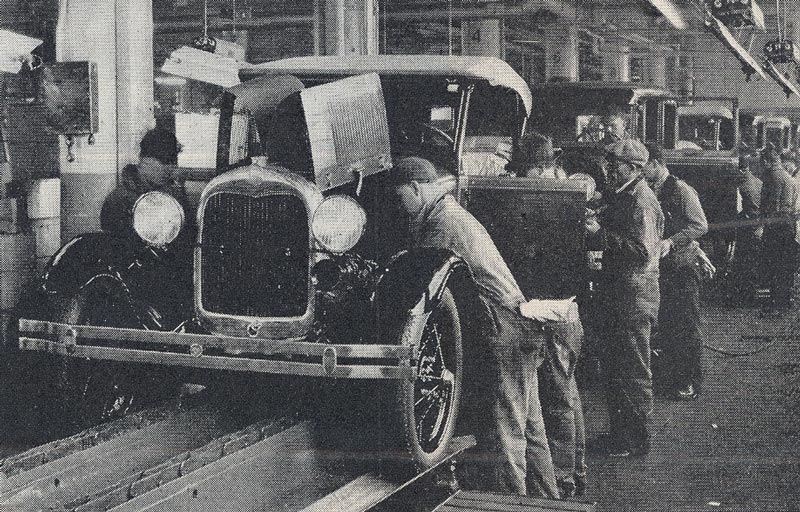

An assembly line is a process of production which enables a continuous efficient rolling process. Usually, it involves a good, such as a car, moving along a conveyor belt. As it moves slowly along, workers add different parts to the car.

Economies of scale and assembly lines

Assembly lines enable economies of scale from the increased specialisation of the workforce. Because workers do a specific job they need less training to be able to a specific task

Assembly line and Ford Motor Cars

The modern assembly line was popularised by the Ford motor car company. In the 1920s Henry Ford piloted an assembly line which significantly cut the costs of producing cars and helped make them affordable for the general workforce.

Problems with assembly lines

- A bottleneck in one place could cause the whole process to come to a complete stop

- Work becomes highly repetitive and boring

- Hard to identify sources of error and maintain quality control

- Assembly lines could lead to diseconomies of scale

Related